The use of PVC blister covers many industries and products: cosmetic packaging, electronic products, gifts and so on. PVC this material has acid, alkali and almost all inorganic chemicals. Although PVC swells or dissolves in aromatics, ketones and cyclic ethers, PVC is insoluble in other organic solvents. With this characteristic, the exhaust pipes produced by PVC, the boards, bottles, pipes and hoses used in buildings are of longer service life. Therefore, from the perspective of tolerance, the service life of PVC blister packaging box is better than other plastic materials.

On the stability of PVC plastic, PVC glue box, in this respect, from the data collected, whether it is the analysis of molecular composition, or the PVC sheet as a tensile test, the results are satisfactory. Because PVC is a chemically stable material, its molecular structure is almost unchanged, and its mechanical strength hardly changes. However, long chain polymers are viscoelastic materials and can be deformed by continuously exerting external forces, even though the applied Li Yuan is lower than its yield point. This is called creep deformation. Although PVC is a viscoelastic material, its creep deformation is very low compared with other plastics because of its limited molecular motion at normal temperature. It is opposite to PET and PP, which has greater molecular motion in the amorphous section. Europe's research in this area shows that some high quality factories now expect to produce PVC pipelines for more than 100 years. This is no doubt a pleasant surprise, which demonstrates from the side that the blister box produced by PVC will have greater durability in service life.

Processability and plasticity are not only PVC, but also some other plastic materials. PET and PP have stronger plasticity themselves. The thermoplastic processing of PVC depends largely on the melt viscosity. Because the melt viscosity of PVC is relatively high, PVC is not suitable for injection molding of large products. On the other hand, the viscoelasticity of PVC is not directly related to the melting temperature at that time. Therefore, PVC is suitable for extrusions of complex shapes (for example, shell material), as well as the calendering and adsorption of wide and thin sheets (such as agricultural film and PVC plastic film, leather, etc.). Polar groups in PVC contribute to coloring, printing and adhesion. PVC products do not require preprocessing and can implement various designs. PVC is used in various decorative applications, making full use of its excellent printability, adhesiveness and weatherability. Making wood decorations on the gate, marble and metal hue are preferred materials.

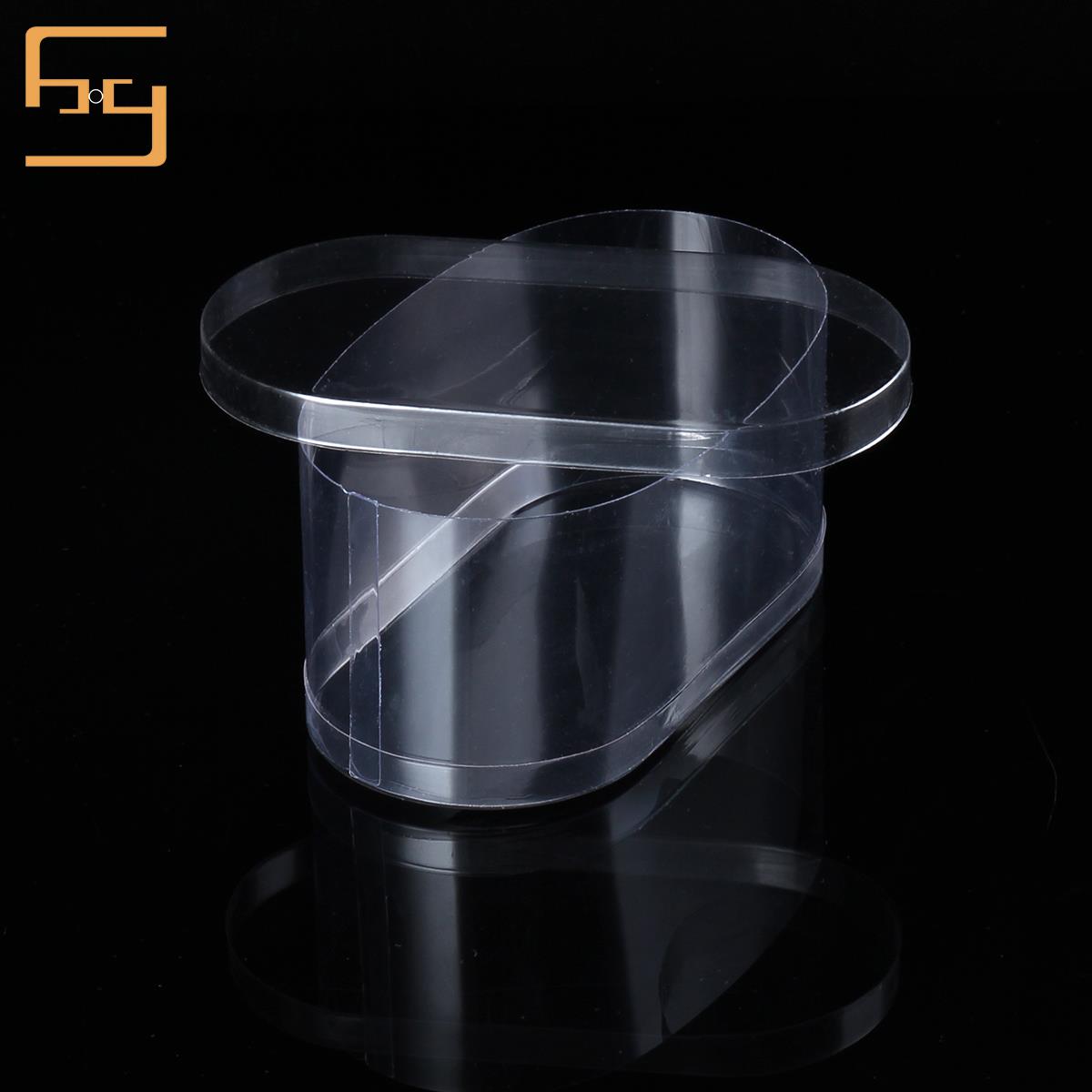

PVC blister box has excellent appearance and can be used for various surface treatment. In the processing of High Frequency Blister box, PVC has always been an irreplaceable material. PVC also has two excellent machining performances in bending, welding, high frequency bonding and vacuum forming as well as field workability. Paste resin processing such as enamel, screen printing and coating is a convenient processing technology, only PVC is feasible.

PVC's amorphous property, for example, is easy to integrate with other materials, and many raw materials are very good with it. So there are a wide variety of plastics produced by the mixture of PVC and other substances, and the physical properties of other plastic products (such as softness, elasticity, impact resistance, pollution prevention, prevention, prevention, and prevention). Microbial growth, anti fogging and flame retardancy can be achieved through the addition or reduction of PVC content and other plasticizers and additives. PVC is the only universal plastic now. By adding plasticizers, additives and modifiers, the physical properties, such as softness, elasticity and impact resistance, are freely, widely and seamlessly adjusted. Compared with the physical properties of polyolefin materials, the difference between the PVC material and the physical properties of polyolefin materials is that the physical properties of the final product can be adjusted by mixing with the additives, so only a few types of formulations will be required to cover all applications (fiber, rigid and flexible plastics, rubber, paint and adhesives). This controllability is also very useful for the recovery of PVC blister packaging manufacturers.

The plastic box, plastic box and blister product produced by PVC are very high in use these years. Apart from PVC blister and plastic box packaging products, other PVC products are more widely used: electronics, architecture, automotive industry, decoration, gifts and so on. It almost spans most of the known industries. The PVC blister product is only one of the small categories.