In the image evaluation process, intelligent object detection replaced simple brightness contrast: HEUFT did not only start to do this now, but has done so more than 20 years ago to improve the detection accuracy on the assembly line and to The error rejection rate is minimized.

In order to classify the detected objects, our image processing has used artificial intelligence (AI) for more than ten years, distinguishing real errors from unobstructed structures (such as water droplets), implementing targeted teaching, and The proportion of qualified products that were incorrectly rejected was reduced to far less than 1%.

The new HEUFT reflexx A.I. camera now also uses intelligent image processing

We have been optimizing HEUFT reflexx A.I. both at the software and hardware level. Intelligent image processing can even be directly integrated into the HEUFT reflexx A.I. camera, which was specially developed for this purpose and can directly process and evaluate your own images in real time. It is not necessary to transfer it to the corresponding testing or testing equipment first. This brings image analysis with learning capabilities to the highest level; the application possibilities of our modular system have reached a whole new level. In order to facilitate the connection with these devices, more functions need to be implemented in the high-speed inspection of empty and full bottles.

And the resolution is much higher. In order to achieve comprehensive detection reliability with the smallest false rejection rate, internally developed hardware and software combine classic image processing methods with modern artificial intelligence technologies (such as target recognition, classification, and learning functions).

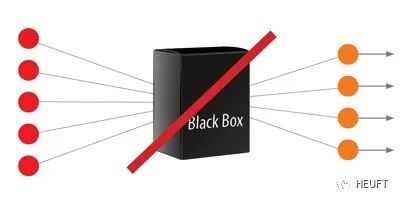

Targeted intervention, not black box

Does this make you completely at the mercy of artificial intelligence, as if you were sitting in a self-driving car without a steering wheel and brake pedal? no! Unlike other suppliers, its evaluation of objects does not come from an unchanging black box containing countless unknowns. On the contrary, humans can intervene in machine learning in a targeted manner:

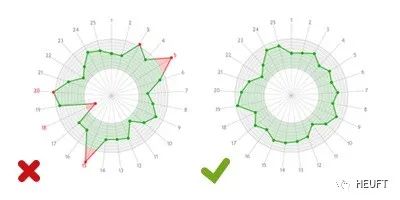

For example, if an unknown object that has never appeared before is detected, AI will evaluate it as an error for security reasons. However, users can always modify the quality assessment based on their own experience and define the identified structure as good and have no critical impact on product and packaging safety, or temporarily tolerate it if necessary. Production can also continue safely without affecting the artificial intelligence network or having to retrain it in a time- and energy-intensive manner. In normal operation, everything will continue to operate fully automatically and with a high degree of safety.

More than just machine learning

If necessary, the assessment can be easily changed at any time: this is the real artificial intelligence! It will not obsolete the expertise of personnel with filling and packaging experience. Instead, it injects image processing analysis when needed. In this way, each individual object can be fully automatically imported into the multi-dimensional feature space and classified separately to distinguish true errors and unobstructed structures (such as water droplets).

Therefore, HEUFT reflexx A.I. combines human artificial intelligence with proven modern image analysis methods to achieve perfect inspection results and guarantee perfect product and packaging quality under unlimited production.

Even now, image processing developed in-house—including HEUFT reflexx A.I. cameras—provides more than simple machine learning. The development of artificial intelligence continues!