Plaster mold: Gypsum mold in semi-wet state, then dry mold, mold is low cost, easy to modify, but the plaster mold accuracy is not high, the surface is not smooth and fragile is not durable, so commonly used plastic tray It comes proofing.

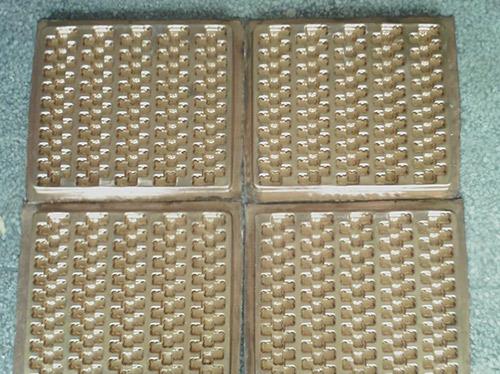

Copper mold: According to the product design requirements, after the plaster mold is made, a plastic tray is produced with a plaster mold, the true plastic tray is placed in the electrolytic cylinder, and when the surface is 5-8 mm thick, the mold is injected into the plaster, and the vacuum pores are injected. , And smooth the mold surface, you can use; takes about 3-5 days; is a metal mold, so more durable, with the mold produced by the plastic tray appearance and transparency is better; mold production price is lower , The use of a wide range, is the preferred mode of the general situation; mainly applies to cosmetics, food, toys, electronics and hardware industries.

Aluminium mold: According to the drawings or templates provided by CAM and other programming software out of the program, by the CNC machine tool processing, and then manually complete other such as pores, undercut position production, and the mold can be polished smooth. Special requirements also need to spray Teflon or sandblasting. It is made of aluminum materials such as ZL401, 6061 and 7075. This mold has high precision, and the product has a beautiful contour and angle, a smooth surface, and a good molding effect. It is the first choice for the production of large quantities of high-grade plastic trays, as opposed to plaster. Mold, copper mold, more durable, saving time and energy, high production efficiency and low scrap rate. The price is also the first of four types of molds; it is mainly applicable to plastic trays such as electronics, gifts, toys, medicine, stationery, etc., which have very high appearance and size requirements.

Shenzhen Xin Hong Yang Packing Co., Ltd., engaged in plastic box customization. Plastic box manufacturer which is better? To find plastic box custom manufacturers, choose Shenzhen Xin Hong Yang Packing Co., Ltd., high-quality transparent plastic box, large output, fast delivery, rapid delivery, quality assurance. Phone: +8613554903780 Fax: +86-755-85207250 E-mail: sales@xhypackaging.com Website: http://www.packaging-box-suppliers.com/